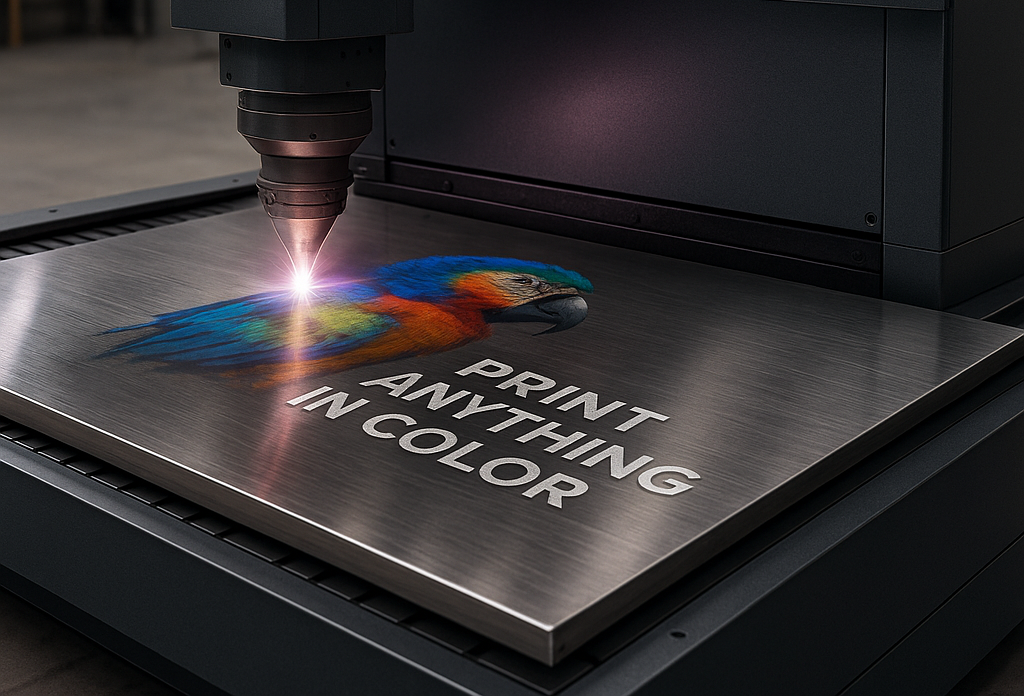

WORLD-FIRST TECHNOLOGY ETCHES FULL COLOUR INTO METAL — FOREVER

Vivid Alloy™ is the world’s first commercial service to permanently engrave full-colour imagery into metal — with no paints, no coatings, and no fading. Using a proprietary laser-fusion process, Vivid Alloy™ embeds rich, vibrant colour directly into the surface of metals like stainless steel, aluminium, and titanium.

“This isn’t ink or powder coating. This is colour, fused into the grain of the metal,” said Olga Arnold, founder of Vivid Alloy™. “It doesn’t scratch off. It doesn’t peel. It’s permanent — and no one else in the world is doing it like this.”

The technology is available now as a service to consumers and businesses looking to create:

-

Custom jewellery (rings, pendants, bracelets)

-

Durable school and medical ID tags

-

Branded metal items (business cards, plaques, signage)

-

Commemorative gifts and awards

With traditional colour treatments on metal prone to wear, fading or chemical breakdown, Vivid Alloy™ offers a sustainable alternative with zero toxic coatings and no consumables.

CUSTOM JEWELLERY

Pendants, rings, bracelets – engraved with vivid art and personal meaning.

SCHOOL & MEDICAL TAGS

Durable ID solutions for students and emergency use.

BRAND & PROMOTIONAL ITEMS

Metal business cards, awards, plaques, and custom gifts.

A New Era for Personalisation and Durability

Each design is rendered in photo-realistic detail, colour-graded, and precision-etched using a proprietary colour-fusion process that blends heat, wavelength, and software control — making the colour part of the metal itself.

If you can imagine it, we can fuse it into steel – Text, logos, artwork — even photos. Once it’s on, it’s on for life.

The service is already being adopted by jewellery designers, schools, military memorabilia makers, and giftware creators who want colour without compromise.

What Makes It Different?

| Feature | Vivid Alloy™ | Traditional Methods |

|---|---|---|

| Colour permanence | ✅ Fused into surface | ❌ Can scratch or fade |

| Durability | ✅ Heat- and scratch-resistant | ❌ Vulnerable to wear |

| Environmental impact | ✅ No paints, no chemicals | ❌ Often uses toxic inks |

| Surface finish | ✅ Sleek, flush, metallic | ❌ Can feel raised or plastic |

| Customisation | ✅ Full-spectrum colour gradients | ❌ Limited shades or monochrome |

Australian-Made. Globally Unique.

Vivid Alloy™ is proudly based in Australia and currently taking custom orders through its online platform. The company also plans to offer B2B services to manufacturers, branding agencies, and hardware providers looking to add permanent colour capability to their products.

The launch has already attracted early buzz from designers and engineering communities. Connell believes this is just the beginning.

“Metal hasn’t changed in decades. We just gave it a new dimension — colour.”